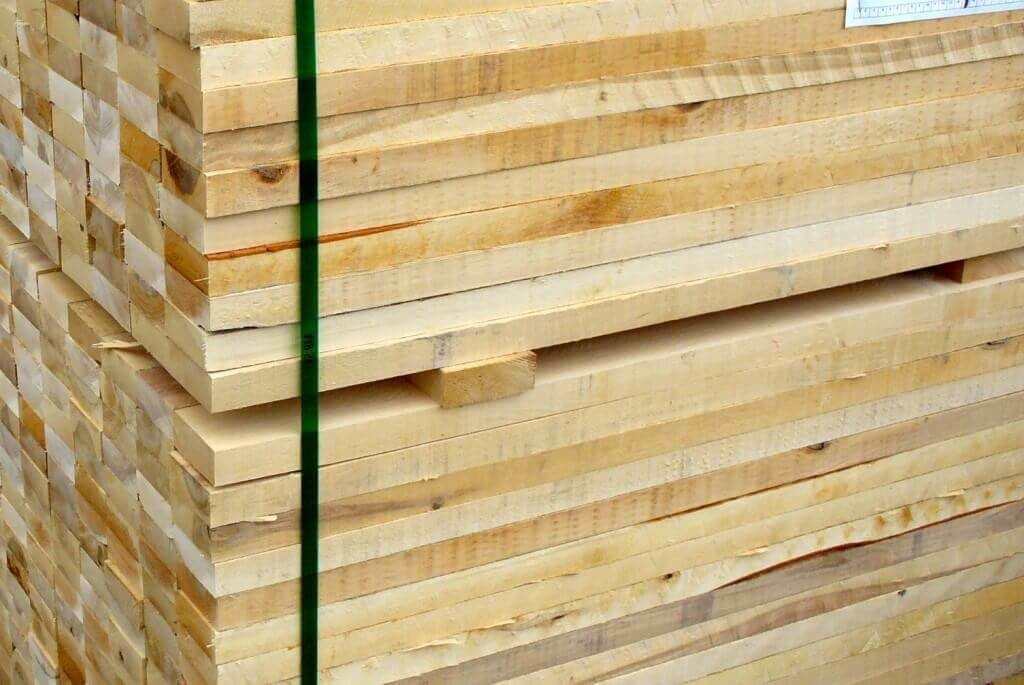

Pre-cut Hardwood

Pallet manufacturers buy cut stock hardwood from Spec Wood for its consistent quality, precise sizing, and reliability. Spec Wood provides durable, high-grade hardwood notched stringers and pallet deck boards that meet industry standards, ensuring longer-lasting pallets. Precut hardwood cut-stock reduces labor costs, minimizes waste, and speeds up production. Spec Wood’s expertise in sourcing and cutting hardwood pallet lumber ensures uniformity, helping manufacturers produce strong, dependable pallets while optimizing productivity and cost-effectiveness.

Our highly successful marketing approach relies on establishing partnerships with our hardwood cut-stock suppliers and customers. We ensure the quality of notched stringers and pallet boards at the mills before merchandise ships to customers. This close working relationship between our pallet component suppliers and our team guarantees high-quality hardwood cut stock and consistency in every load, bundle, and grade of pallet lumber we offer.

We cut: 1/2’’, 9/16’’, 5/8’’, 11/16’’, 3/4’’ and 7/8’’ boards as well as 1 1/8’’, 1 1/4’’, 1 3/8’’, 1 1/2’’, 1 5/8’’, 1 3/4’’, 1 7/8’’, 2 1/2’’, 2 3/4’’ and 2 7/8’’ plain or notched stringers.

Heat-treated options are also available for some of the above products.